Transforming Energy Generation with Innovation and Expertise

We excel in addressing our clients’ digital transformation needs, enhancing the experience for millions of users.

CMS – Continuous Measurement System

Leveraging our robust technological infrastructure, we deliver holistic and efficient solutions to ensure the optimization and dependability of your power generation equipment. Our tool maintains a constant vigilance over the equipment:

- Captures, stores, manages, and displays precise information on performance and efficiency.

- Detailed real-time information to prevent unscheduled downtime and maximize operational efficiency.

- Facilitates decision-making and early detection of changes or deviations

- Optimizes processes.

- Detects potential issues or anomalies at early stages.

- Reduced expenses for emergency repairs and replacements.

- Minimizes unplanned downtime.

Our technological solution is designed to assist companies in enhancing efficiency, reducing operational costs, and improving sustainability through the implementation of various steps:

of signal acquisition hardware.

information and analysis.

and processing.

for information management.

Artificial Intelligence.

Capturing and Processing Signals.

Our solution captures and processes signals, which are then converted into digital format.

Analysis and Diagnosis.

Our solution employs a range of specialized techniques to conduct thorough analyses and diagnoses of operational equipment.

Software development for information management. Among its capabilities, the software allows for the customization of specific parameters, indices, alerts, signal processing time scale, as well as comparisons, and more.

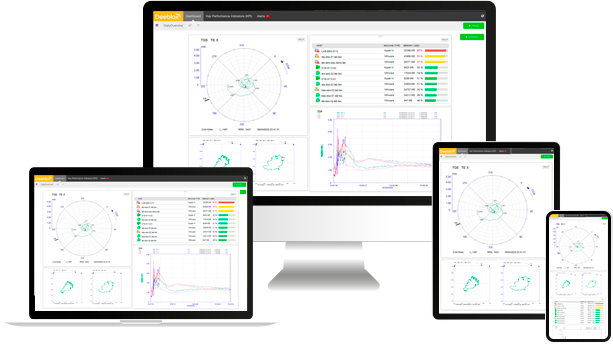

Exploitation of information and analysis. We can generate personalized information dashboards that enable efficient real-time data visualization and analysis.

Application of Artificial Intelligence to identify design patterns and uncover occurrences of unspecified, new patterns.

Security and traceability. Our system is designed to comply with audit standards, and we employ advanced security techniques to ensure data protection throughout the data lifecycle.

SERVICES

Our range of services is the outcome of organizing the modules comprising our SMC into a service offer format.

We recognize that our major value proposition lies in the holistic approach, designed as a solution. Yet, we understand that needs vary, and so do the ways to kickstart projects.

Delivering one of our offered services frequently bolsters our rapport with clients who, much like us, aim for long-term relationships founded on accountability and trust.

Information Dashboard Generation encompasses the collection of data from diverse sources, including databases, transactional systems, analytical tools, and external outlets. This data is then structured and translated into graphical representations, such as charts, tables, indicators, and maps, offering a lucid and comprehensible portrayal of the business’s status and performance.

Employing Information Dashboard Generation presents an efficient and effective means to monitor and scrutinize business performance. Through the visual representation of data, users can pinpoint trends, patterns, and areas ripe for enhancement, thereby streamlining the process of making well-informed, strategic decisions.

Here are some of the key features of our information dashboards:

Customization.

Information dashboards can be customized to meet the specific requirements of individual users or departments. This includes configuring visualizations, selecting relevant KPIs, and applying filters to display only the essential information.

Interactivity.

Information dashboards are typically interactive, enabling users to delve into data details, conduct ad hoc analyses, and retrieve specific information by clicking on visual elements.

Real-time Updates.

The information dashboards can update automatically based on the availability of new data. This enables making decisions based on up-to-date information and staying informed about real-time changes.

Multi-Device Accessibility.

The information dashboards are accessible from a range of devices, including desktop computers, tablets, and mobile phones. This ensures convenient access to key information regardless of time or location.

Alerts and Notifications System.

Specific information dashboards offer the feature of setting up alerts and notifications, keeping users informed about particular events or conditions. This allows for a swift identification of any deviations or performance issues.

Data repository architecture is a set of principles and structures designed to efficiently manage and organize data within an organization. This service focuses on the storage, access, and control of data in various formats and sources, with the aim of facilitating its use and maximizing its value for the company.

In a typical data repository architecture, different components and layers are used to address the specific needs of the organization. These may include

Centralized Storage

A central repository is established where data is securely stored and accessible. This can take the form of a database system, a data warehouse, or a cloud storage system.

Data integration

Mechanisms are put in place to integrate data from various sources, such as transactional databases, legacy systems, external applications, and web services. This involves transforming, cleaning, and standardizing the data to ensure its coherence and quality.

Metadata

Metadata is used to describe the data and provide additional information about its origin, meaning, and structure. This facilitates users in searching, discovering, and understanding the data.

Security and Access Control

Security measures are implemented to protect sensitive data and ensure that only authorized users have access to it. This may include authentication, authorization, encryption, and access auditing.

Data Governance

Policies and processes are established to effectively manage data. This involves defining responsibilities, setting data quality standards, managing changes, and ensuring compliance with regulations.

Presentation Layer

Tools and interfaces are provided for users to access and visualize data in an intuitive manner. This may include interactive dashboards, custom reports, ad hoc queries, and APIs for integration with other applications.

We provide a comprehensive solution that combines these technological capabilities to enhance the efficiency and reliability of equipment.

Below, each of the capabilities is described along with how they are applied in this service:

Artificial Intelligence (AI)

AI is used to create intelligent systems capable of simulating human thinking and making data-driven decisions.

In the context of rotating machinery, AI can analyze patterns, recognize anomalies, and perform automatic diagnostics. For example, by training AI algorithms with historical data from operating machinery, it is possible to identify patterns of normal behavior and detect deviations or potential failures in real time

Machine Learning

Machine Learning is a subset of AI that empowers machines to learn and enhance their performance through experience and ongoing feedback.

In the realm of rotating machinery, machine learning algorithms prove invaluable for analyzing extensive datasets collected from sensors and monitoring systems. They excel at uncovering latent patterns, forecasting future performance, and offering recommendations to optimize maintenance and avert potential failures.

Big Data

Big Data encompasses the processing and analysis of extensive datasets that are too complex or voluminous for conventional methods.

In the realm of rotating machinery, vast quantities of real-time data can be collected, including vibrations, temperature, pressure, energy consumption, among others. These datasets are stored and analyzed using Big Data technologies to extract invaluable insights, discern wear patterns, evaluate equipment health, and make predictive maintenance decisions based on concrete data.

The service for optimizing maintenance of rotating machinery using AI, Machine Learning, and Big Data focuses on maximizing equipment availability, minimizing maintenance costs, and preventing catastrophic failures. By applying these technological capabilities, the following benefits can be achieved:

Real-time Monitoring: Continuous monitoring sensors and systems enable the collection of real-time data, providing an up-to-date view of the status of rotating machinery.

Predictive Maintenance:

Using machine learning algorithms, it’s possible to predict potential failures or issues before they occur, allowing for proactive maintenance scheduling and preventing unplanned downtime.

Resource Optimization:

Analyzing both historical and real-time data enables the identification of wear patterns and the optimization of maintenance intervals, thereby avoiding unnecessary tasks and maximizing the use of resources such as labor and spare parts.

Cost Reduction:

By preventing failures and efficiently scheduling maintenance, costs associated with major repairs, unplanned downtime, and production losses are reduced.

Mejora de la productividad:

La optimización del mantenimiento y la disponibilidad de las máquinas rotantes permiten una mayor productividad en las operaciones, ya que los equipos se encuentran en óptimas condiciones de funcionamiento.

Crafting bespoke software solutions, we facilitate the efficient processing and management of data generated by your equipment.

Our team comprises highly qualified developers who are continuously updating their skills and expertise.

These measurements provide crucial information for identifying issues, assessing the health status of equipment, and making precise diagnoses.

Some of the techniques we employ include:

Mechanical Vibrations:

Mechanical vibration measurements are techniques employed to quantify and analyze the oscillations or vibratory movements of a mechanical system. These measurements furnish essential information for issue identification, equipment health assessment, and accurate diagnostics.

- Frequency Analysis

- Waveform Analysis

- Spectral Analysis

- Orbit Analysis

- Envelope Analysis

Acoustic Emission:

Acoustic emission measurement is a technique employed to detect and assess acoustic signals produced by phenomena like fractures, cracks, wear, corrosion, or other defects in materials and structures.

- Event Detection:

- Continuous Monitoring

- Signal Analysis

- Source Localization

- Assessment of Structural Integrity

Structural Testing:

Structural tests conducted on rotating machinery are performed to evaluate and understand the behavior and strength of moving mechanical components, including turbines, engines, pumps, and other rotating equipment.

- Structural Integrity Assessment

- Fault or Weakness Detection

- Design Optimization

- Verification of Compliance with Standards and Regulations

Non-Destructive Testing:

Non-Destructive Testing (NDT) techniques applied to rotating machinery allow for the evaluation and detection of defects or anomalies in components without causing any damage. These tests play a crucial role in preventing failures, extending equipment lifespan, planning maintenance, and ensuring the safety of operations.

- Crack and Defect Detection

- Corrosion and Wear Assessment

- Quality Control in Manufacturing

- Long-Term Integrity Monitoring

- Assessment of Bearings and Lubrication Systems

CASOS DE ÉXITO

NuclearTech

NuclearTech nos eligió con el objetivo de profundizar y optimizar el funcionamiento de sus equipos.

Iniciamos un proyecto de medición en su planta, incorporando sensores avanzados para recolectar datos en tiempo real sobre temperaturas, vibraciones y rendimiento de su maquinaria crítica.

Estos datos se convirtiendo en información valiosa mediante el uso de análisis de inteligencia artificial. El sistema detectaba patrones y anomalías, alertando sobre posibles problemas en la maquinaria. Lo más destacado fue la implementación de un sistema de alerta temprana que notificaba al equipo de operaciones y supervisores en tiempo real, permitiendo la intervención antes de que los problemas se agravaran.

Los resultados hablaron por sí mismos:

- Se mejoró el tiempo de inactividad no programado

- Aumentó la disponibilidad y seguridad de la planta

- Se optimizaron las operaciones

- Se estableció un estándar para la seguridad

NuclearTech

NuclearTech nos eligió con el objetivo de profundizar y optimizar el funcionamiento de sus equipos.

Iniciamos un proyecto de medición en su planta, incorporando sensores avanzados para recolectar datos en tiempo real sobre temperaturas, vibraciones y rendimiento de su maquinaria crítica.

Estos datos se convirtiendo en información valiosa mediante el uso de análisis de inteligencia artificial. El sistema detectaba patrones y anomalías, alertando sobre posibles problemas en la maquinaria. Lo más destacado fue la implementación de un sistema de alerta temprana que notificaba al equipo de operaciones y supervisores en tiempo real, permitiendo la intervención antes de que los problemas se agravaran.

Los resultados hablaron por sí mismos:

- Se mejoró el tiempo de inactividad no programado

- Aumentó la disponibilidad y seguridad de la planta

- Se optimizaron las operaciones

- Se estableció un estándar para la seguridad

NuclearTech

NuclearTech nos eligió con el objetivo de profundizar y optimizar el funcionamiento de sus equipos.

Iniciamos un proyecto de medición en su planta, incorporando sensores avanzados para recolectar datos en tiempo real sobre temperaturas, vibraciones y rendimiento de su maquinaria crítica.

Estos datos se convirtiendo en información valiosa mediante el uso de análisis de inteligencia artificial. El sistema detectaba patrones y anomalías, alertando sobre posibles problemas en la maquinaria. Lo más destacado fue la implementación de un sistema de alerta temprana que notificaba al equipo de operaciones y supervisores en tiempo real, permitiendo la intervención antes de que los problemas se agravaran.

Los resultados hablaron por sí mismos:

- Se mejoró el tiempo de inactividad no programado

- Aumentó la disponibilidad y seguridad de la planta

- Se optimizaron las operaciones

- Se estableció un estándar para la seguridad

CORPORATE SOCIAL RESPONSIBILITY.

CSR is a fundamental pillar at Deeblox. We take pride in working with open technology and basing our academic foundations, as we firmly believe in the importance of technological inclusion and knowledge transfer to build a more equitable and sustainable future.

Our commitment is reflected in our concrete actions:

We strive to promote technological inclusion by providing access and opportunities to different sectors of society. We aim to narrow the digital divide by offering innovative and accessible technological solutions that can be adopted by various industries and communities.

We actively promote knowledge transfer through collaborations with educational institutions, non-profit organizations, and other companies. We believe in the importance of sharing our expertise and working together to drive technological development and strengthen the capabilities of individuals and communities.

We endeavor to be agents of positive change in our society and environment. We seek to minimize our environmental impact through sustainable practices in our operations and promote the adoption of clean technologies in the energy generation industry and beyond.

We value diversity and equal opportunities in our team and in our interactions with clients and partners. We foster an inclusive and respectful environment where every voice is valued and every perspective is considered.

CONTACT